We look forward to your visit on facebook.

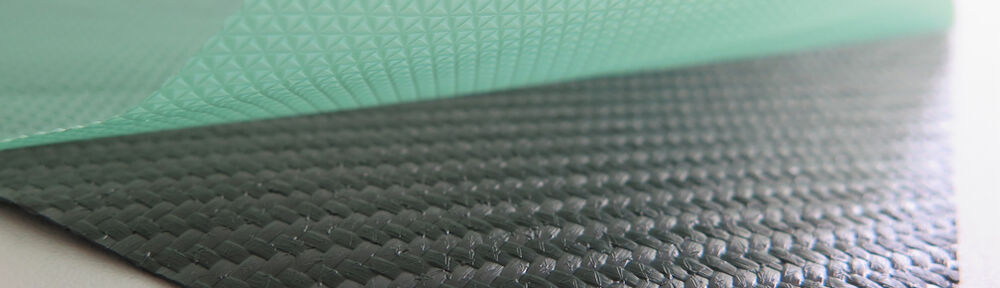

Whenever a maximum performance is needed in composite construction, prepregs (pre-impregnated) are used. A consistently low fibre volume ratio and a perfect impregnation of the fibre enable the production of efficient fibre reinforced components. For the controlled, non-porous cure of the components autoclaves are used. We're happy to meet your individual requirements and can deliver the required fibres an the necessary profile on short notice.

| Art.No. | Name | Curing Time/°C | max. TG | Application | Width mm | Roll length lfm | Data sheet | |

|---|---|---|---|---|---|---|---|

| HACOPREG MTP126S | Middle temperature prepreg | 12h@80°C 1h@120°C 15min.@140°C | 125- 130°C | Especially for viewable components, high transparent, strength for application in the field of automotive, nautical and sporting industries | 1000 | 50 | |

The prepregs are manufactured in combination with our standard fabric types according to the customers' request. Should you not find the required material for your purpose, don't hesitate to contact us. We'll develop a tailor made solution for you!

Forged Carbon

| Art.No. | Name | Curing Time/°C | max. TG | Application | Width mm | |

|---|---|---|---|---|---|

| CMC070B | Middle temperature carbon Moulding compound | 8h@80°C (TG 105°C) to 15min@140°C (TG 125°C) | 130°C | High tensile strength, carbon fiber length 6 mm. Processing from 70°C in autoclave or pressing processes, automotive, marine, sports articles | |

| CMC080- 25/50 | Middle temperature carbon Moulding compound | 8h@80°C 1h@120°C 15min@140°C | 105- 130°C | High tensile strength, carbon fiber length 25 or 50 mm. Processing from 80°C in autoclave or pressing processes, automotive, marine, sports articles | 480 |